We are pleased to launch our new product, PE Easy Peel T60, which is used for laminated tube top sealing.

This is an aluminum top seal customized according to the special needs of a customer.

We know that when designing the die-cutting mold of the top seal, it is usually provided with an extended pull ear for consumers to pull and open.

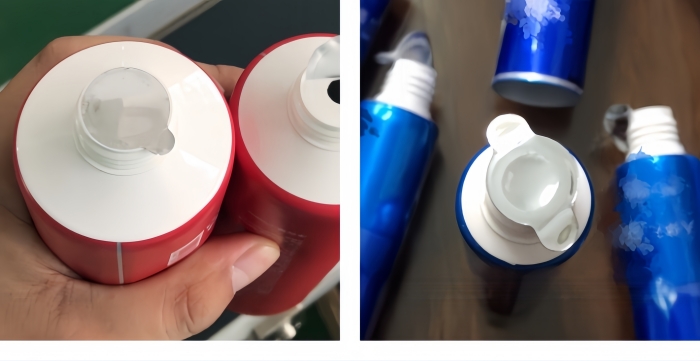

When sealing the laminate tube, the extended pull ear needs to be folded up or down before sealing. The problem that the ear may cause is that when the top seal is folded back, the top seal at the folded part is thicker, which will cause the sealing to be loose when sealing on the heat sealing machine, resulting in leakage; and when the ear is folded down and then sealed, after sealing is suspended at the thread of the tube orifice. After capped, the ear at the thread is easily pulled and pressed, causing the ear of the seal to tear, which will also cause leakage.

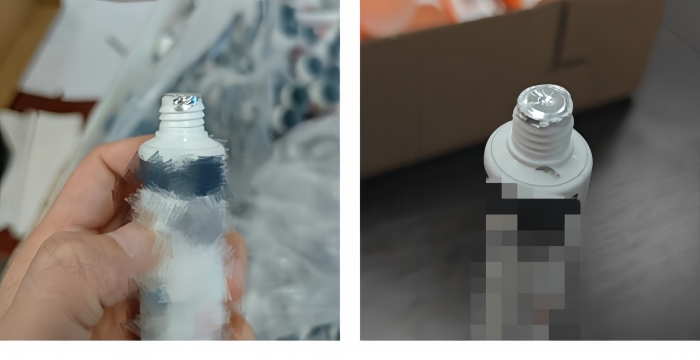

This is the problem with te customer's existing aluminum sealing foil. After the seal is closed, it is easy to pull off, and most of it will tear, and even the top sealing part will shift, which greatly increases the risk of leakage. Obviously, the customer's tube head mold design precision is relatively high, and the gap between the tube thread and the cap is small, which leads to the above problems. )

We first suggested that the customer try to turn the ear upward to see if there would be more space upward to solve the problem of tearing after twisting the thread downward, but the customer's equipment could not achieve it. Finally, we newly developed PE Easy Peel T60, using 30um aluminum foil as a barrier layer to ensure the barrier performance of the top seals. Under this premise, the overall thickness of the top seal is thinned. At the same time, 6um PET can help maintain its stiffness without increasing the thickness of the top seal. And the PE layer is also customized according to our unique formula to ensure the heat sealing

effect and easy peeling effect. After customer testing, the customer's problem was completely solved.

Top Seal foil for tubes is a simple but also complex product. The complexity lies in that we must first ensure the sealing of the product and at the same time ensure its easy peel. And there are thousands of tube manufacturers (ABL Tube, PBL Tube, Plastic extruded tube), and everyone uses different equipment with different speeds and pressures. At the same time, the formula of the tube is also different, so the use of the top seal is relatively complex.

Jiben Packaging currently has more than 400 customers. We have rich product experience and problem-solving experience. If you have similar problem products, please contact us.

Contact: Fatima

Phone: +86 15360563041

E-mail: fatima@gyjaluminum.com

Whatsapp:+86 18028752109

Add: No. 481 Guangming Avenue, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen City, Guangdong Province, Lefu Square 1B909-910

We chat